Concentration of Ores

Concentration of Ores is a crucial step in metallurgy that involves removing impurities (gangue) to enrich the ore and increase the percentage of metal. This process improves the efficiency of extraction methods such as smelting, leaching, and electrolysis, making them more economical and effective.

Table of contents

- Why Concentrate Ores?

- Methods of Concentration

- Importance of Concentration

- Quiz

- MCQs

- FAQ

- References & Links

Why Concentrate Ores?

Natural ores contain gangue (unwanted minerals like soil, sand). Concentration removes gangue to:

- Increase metal percentage

- Improve efficiency of extraction (smelting, hydrometallurgy)

- Reduce transport & processing costs

- Minimize waste and environmental impact

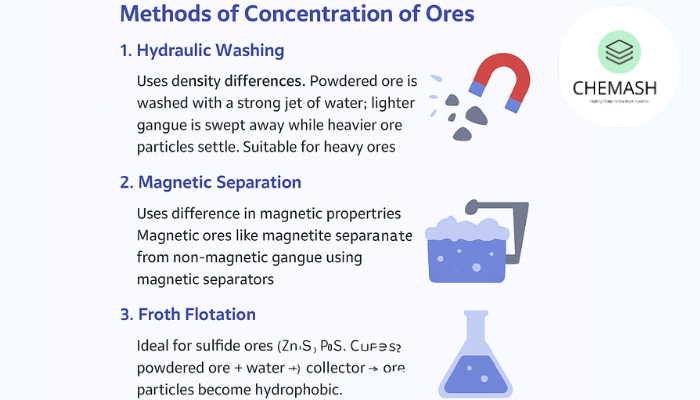

Methods of Concentration of Ores

The method chosen depends on ore type, particle size and impurities. Common methods are:

1. Hydraulic Washing

Uses density differences. Powdered ore is washed with a strong jet of water; lighter gangue is swept away while heavier ore particles settle. Suitable for heavy ores like tin, gold, and lead.

Concentration of ores is the process of removing gangue to enrich metal content, improving efficiency and economy of metal extraction. Learn methods, importance, examples and test your knowledge.

2. Magnetic Separation

Separates magnetic ores (e.g., magnetite) from non-magnetic gangue using magnetic separators. Efficient and commonly applied to iron ore processing.

3. Froth Flotation

Ideal for sulfide ores (ZnS, PbS, CuFeS2). Powdered ore + water + collector → ore particles become hydrophobic. Air is bubbled through; hydrophobic ore particles attach to bubbles and rise as froth which is skimmed off; gangue sinks.

Tip: For a practical overview of froth flotation see the external summary on Wikipedia: Froth flotation (Wikipedia).

4. Leaching

Ore is treated with a solvent that selectively dissolves the metal (acidic, alkaline or cyanide solutions depending on the metal). The metal-rich solution is then processed (precipitation, solvent extraction, electrowinning) to recover metal. Common for low-grade or complex ores (bauxite, gold, uranium).

Importance of Concentration of Ores

Concentration increases metal content and reduces fuel and reagent consumption during smelting and refining. It lowers environmental footprint by reducing tailings volume and makes extraction economically viable for low-grade ores.

Quiz: Concentration of Ores

Q1: What is the main purpose of concentrating ores?

Answer: To remove impurities (gangue) and increase the metal percentage, making extraction economical.

Explanation: Higher ore grade reduces energy and reagent consumption in later steps.

Q2: Which method is suitable for magnetic ores?

Answer: Magnetic separation.

Explanation: Magnetic separators exploit differences in magnetic susceptibility between ore and gangue.

Q3: Briefly explain froth flotation.

Answer: Powdered ore mixed with water and collector chemicals; air bubbles carry hydrophobic ore particles to form froth which is collected, separating ore from gangue.

Explanation: Widely used for sulfide ores where surface chemistry is tuned to make ore particles hydrophobic.

Q4: Why is hydraulic washing effective for some ores?

Answer: It uses density differences — lighter impurities are washed away while heavier ore particles remain.

Explanation: Best for coarse, heavy ores where size and density differences are large.

Q5: What role does leaching play?

Answer: Leaching dissolves metal into solution so it can be separated from solid gangue — ideal for low-grade or refractory ores.

Explanation: Followed by purification and metal recovery steps like precipitation or electrowinning.

Multiple Choice Questions

- Which method uses a water jet to remove lighter impurities?

a) Magnetic separation

b) Hydraulic washing

c) Froth flotation

d) Leaching Explanation: Hydraulic washing relies on density and water flow to separate gangue. - Froth flotation is mainly used for:

a) Oxide ores

b) Sulfide ores

c) Native metals

d) Clay minerals Explanation: Collectors make sulfide particles hydrophobic for bubble attachment. - Which method dissolves metal using solvents?

a) Hydraulic washing

b) Magnetic separation

c) Froth flotation

d) Leaching Explanation: Leaching uses chemical solvents (acids, cyanide etc.) to dissolve target metals. - Magnetic separators are effective for:

a) Galena (PbS)

b) Magnetite (Fe₃O₄)

c) Bauxite

d) Gold Explanation: Magnetite is strongly magnetic and easily separated from non-magnetic gangue. - Why concentrate low-grade ores?

a) To increase moisture content

b) To make extraction economical

c) To add gangue

d) To reduce metal content Explanation: Concentration upgrades ore grade and reduces costs of downstream processing.

MCQ Answers

- b) Hydraulic washing

- b) Sulfide ores

- d) Leaching

- b) Magnetite (Fe₃O₄)

- b) To make extraction economical

Frequently Asked Questions

Q: Can froth flotation be used for oxide ores?

A: Froth flotation is primarily for sulfide ores, but with modified reagents and conditioning it can be adapted for some oxide ores. Q: Is leaching environmentally safe?

A: Leaching can pose environmental risks (e.g., cyanide use in gold extraction). Modern operations implement containment, detoxification, and strict regulation to minimize impact.

Q: Where can I read more about ore concentration techniques?

A: Good resources include mineral processing textbooks and reviews. External overview: Mineral processing (Wikipedia). Internal link: Metallurgical Processes (CHEMASH).