Raw Materials for Cement Production – Composition, Sources, and Uses

Cement is produced by heating a mixture of raw materials into clinker, which is later ground into fine cement powder. These raw materials provide essential oxides like calcium, silicon, aluminum, and iron, making them vital for high-quality cement production. Raw Materials for Cement Production

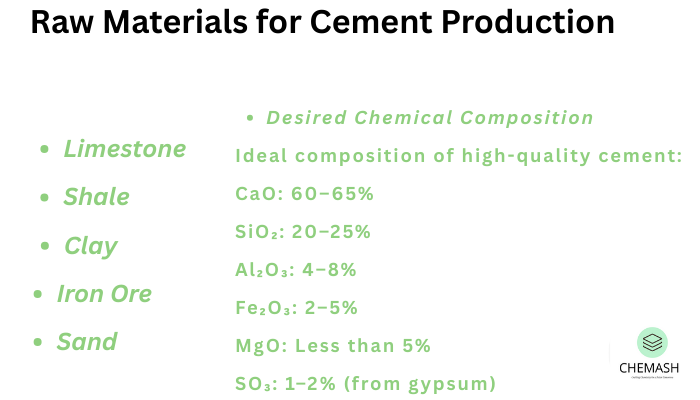

Major Raw Materials

- Limestone (CaCO₃): Main source of calcium oxide (CaO), about 60–65% of the raw mix. Provides strength and structure.

- Clay or Shale: Sources of silica (SiO₂), alumina (Al₂O₃), and iron oxide (Fe₂O₃). Maintains chemical balance.

- Sand (Silica): Enhances silica content for improved hardness.

- Iron Ore: Supplies iron oxide (Fe₂O₃), helping clinker formation and cement’s grey color.

Minor Additives

- Bauxite: Adds alumina when clay is insufficient.

- Gypsum (CaSO₄·2H₂O): Regulates cement setting time.

- Magnesite (MgCO₃): Provides magnesia (MgO), improves durability in small amounts.

Desired Chemical Composition

Ideal composition of high-quality cement:

- CaO: 60–65%

- SiO₂: 20–25%

- Al₂O₃: 4–8%

- Fe₂O₃: 2–5%

- MgO: Less than 5%

- SO₃: 1–2% (from gypsum)

Conclusion

The quality of cement relies on proper selection and proportioning of raw materials. Correct blending ensures strength, durability, and controlled setting time of the final product.

Related: Manufacturing Process of Cement

Reference: CemNet – Global Cement Knowledge

Quiz: Raw Materials for Cement Production

- Which raw material provides the main source of calcium in cement?

a) Clay

b) Gypsum

c) Limestone

d) Bauxite - Which is added to cement to control setting time?

a) Bauxite

b) Iron ore

c) Gypsum

d) Silica - Iron oxide (Fe₂O₃) mainly contributes to:

a) Early strength

b) Stability

c) Heat resistance

d) Grey color and clinker formation - Which raw material increases silica content?

a) Magnesite

b) Sand

c) Limestone

d) Gypsum - Typical CaO (Calcium Oxide) content in cement is:

a) 20–25%

b) 40–45%

c) 60–65%

d) 75–80%

Answers & Explanations

- 1. c) Limestone – Source of CaO (60–65%).

- 2. c) Gypsum – Controls setting time.

- 3. d) Grey color & clinker formation – Role of Fe₂O₃.

- 4. b) Sand – Adds silica content.

- 5. c) 60–65% – Ideal CaO in cement.

FAQs on Cement Raw Materials

Q1: Why is limestone the most important raw material?

A1: Because it provides calcium oxide, the major component of cement.

Q2: What happens if gypsum is not added to cement?

A2: Cement would set too quickly (flash setting), making it unusable in construction.

Q3: Can magnesia content be high in cement?

A3: No, excessive MgO causes expansion and cracking. It should be <5%.

Q4: Which oxide contributes to cement color?

A4: Iron oxide (Fe₂O₃) gives cement its grey shade.