Glass is a non-crystalline, transparent or translucent material widely used in windows, bottles, optics, and construction. It is primarily composed of silica and modified by other materials to enhance properties such as durability, color, melting point, and workability. Raw Materials for Glass Manufacturing

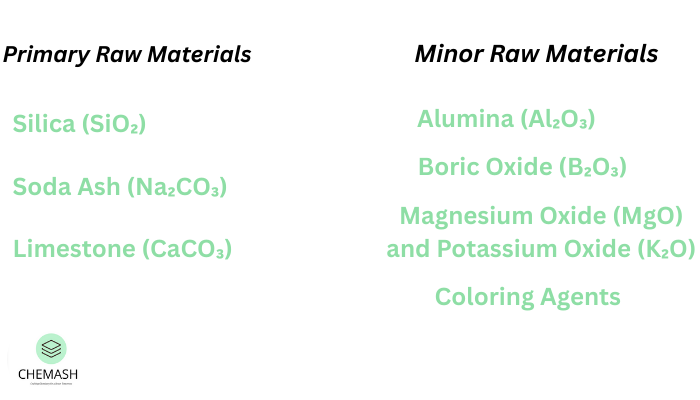

Primary Raw Materials for Glass Manufacturing

- Silica (SiO₂): The main glass-forming oxide. It constitutes 70–75% of the glass mixture. Obtained from sand or quartz, it provides transparency and chemical resistance.

- Soda Ash (Na₂CO₃): Acts as a flux to lower the melting point of silica. It improves workability and reduces energy cost.

- Limestone (CaCO₃): Supplies calcium oxide (CaO), which enhances the chemical durability and hardness of glass.

Minor Raw Materials and Modifiers in Glass Production

- Alumina (Al₂O₃): Increases strength and weather resistance.

- Boric Oxide (B₂O₃): Lowers thermal expansion and increases resistance to heat (used in borosilicate glass).

- Magnesium Oxide (MgO) and Potassium Oxide (K₂O): Modify refractive index and viscosity.

- Coloring Agents: Added to produce colored glass:

- Iron oxide (Fe₂O₃): Green or brown tint

- Cobalt oxide (CoO): Blue glass

- Manganese dioxide (MnO₂): Violet glass

Functions of Raw Materials in Glass Manufacturing

- Formers: e.g., SiO₂ – essential for the glass network structure.

- Fluxes: e.g., Na₂CO₃ – lower melting point and improve fusion.

- Stabilizers: e.g., CaCO₃ – improve hardness, water resistance, and thermal properties.

- Colorants: Provide aesthetic value or functional properties (e.g., UV protection).

Summary of Glass Manufacturing Raw Materials

The quality and properties of glass depend on the proportion and purity of raw materials. A precise mix of silica, soda ash, and stabilizers ensures the desired optical, mechanical, and chemical characteristics for different applications.

Quiz on Raw Materials for Glass Manufacturing

- Which of the following is the primary glass-forming oxide?

a) CaO

b) SiO₂

c) Al₂O₃

d) Na₂CO₃

Answer: b) SiO₂

Explanation: Silica (SiO₂) is the base material that forms the network structure of glass. - What is the function of soda ash (Na₂CO₃) in glass manufacturing?

a) Provides hardness

b) Acts as a coloring agent

c) Reduces the melting point

d) Adds strength

Answer: c) Reduces the melting point

Explanation: Soda ash lowers the melting temperature of silica, improving efficiency and flow. - Which component improves the durability and water resistance of glass?

a) CaCO₃

b) B₂O₃

c) MnO₂

d) CoO

Answer: a) CaCO₃

Explanation: Calcium from limestone strengthens and stabilizes the glass structure. - Which raw material is used to create blue-colored glass?

a) Manganese dioxide

b) Cobalt oxide

c) Iron oxide

d) Potassium oxide

Answer: b) Cobalt oxide

Explanation: Cobalt oxide imparts a deep blue tint to glass. - Which raw material reduces the thermal expansion of glass, useful in labware?

a) Al₂O₃

b) K₂O

c) B₂O₃

d) Fe₂O₃

Answer: c) B₂O₃

Explanation: Boron oxide improves thermal resistance and is used in borosilicate glass (e.g., Pyrex).

Related Reading : Learn about the full Glass Manufacturing Process.

External Resource: For further study, check Glass on Wikipedia.

Pingback: Recycling and Environmental Impact of Glass - CHEMASH