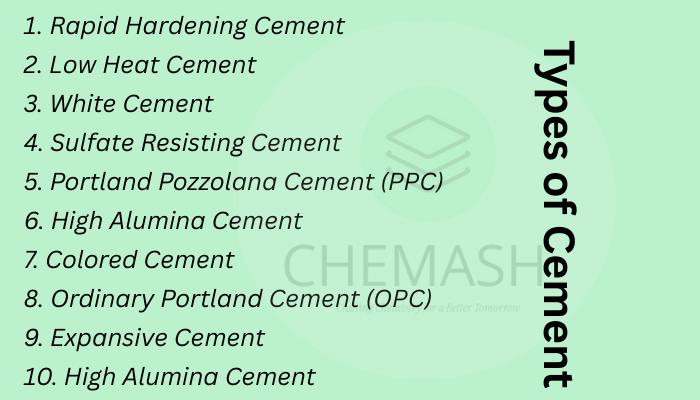

Cement is a key ingredient in construction, acting as a binder for concrete and mortar. Different types of cement are used depending on structural, environmental, or durability requirements. Each type has distinct chemical composition and properties that suit unique applications. (Reference: Wikipedia)

1. Ordinary Portland Cement (OPC)

Most commonly used cement in construction. It is classified into three grades: 33, 43, and 53.

- Used in: Buildings, pavements, bridges

- Strength: High early strength (53 grade most popular)

2. Portland Pozzolana Cement (PPC)

PPC is made by blending OPC with pozzolanic materials like fly ash, volcanic ash, or silica fumes.

- Used in: Hydraulic structures, marine works, sewage plants

- Properties: Better workability, reduced heat of hydration

3. Rapid Hardening Cement

Develops strength faster than OPC, ideal for urgent projects.

- Used in: Road repairs, precast units, cold weather concreting

4. Low Heat Cement

Generates less heat during hydration, reducing risk of cracks in mass concrete.

- Used in: Dams, retaining walls, large foundations

- Benefit: Minimizes thermal cracking

5. Sulphate Resisting Cement

Resists chemical attack from sulfates in soil and groundwater.

- Used in: Marine works, sewage plants, foundations in sulphate soil

- Advantage: Prevents steel corrosion

6. White Cement

Manufactured using raw materials free of iron oxide and manganese.

- Used in: Decorative works, flooring, tile adhesives

- Appearance: Bright white, mixable with pigments

7. Colored Cement

Produced by adding pigments to white cement.

- Used in: Decorative flooring, pavement tiles

8. High Alumina Cement

Made by fusing bauxite and limestone; contains 35–80% alumina.

- Used in: Refractory works, high-temperature areas

- Benefit: Quick setting and high early strength

9. Expansive Cement

Expands slightly during setting to offset shrinkage.

- Used in: Grouting, anchoring, sealing pipe joints

Quiz: Test Your Understanding

1. Which type of cement is best for marine structures?

A) OPC

B) Sulphate Resisting Cement

C) White Cement

D) High Alumina Cement

Answer: B – It resists sulphate attack.

2. What distinguishes PPC from OPC?

A) Higher strength

B) Lower cost

C) Pozzolanic materials

D) Limited to roads

Answer: C – PPC includes fly ash/volcanic ash.

3. Which cement is chosen for aesthetics?

A) Colored Cement

B) Sulphate Resisting

C) Rapid Hardening

D) Low Heat

Answer: A – Colored Cement is decorative.

4. Why is Low Heat Cement used in dams?

A) Faster setting

B) Reduces thermal cracks

C) Contains pigments

D) Higher alumina

Answer: B – Releases less hydration heat.

True/False Practice

- OPC is the only type of cement used worldwide. ❌ False

- Low Heat Cement is suitable for mass concreting. ✅ True

- White cement is made using iron-rich raw materials. ❌ False

- PPC is more eco-friendly than OPC. ✅ True

Fill in the Blanks

1. ______ cement is used where resistance to sulphate attack is required.

(Answer: Sulphate Resisting Cement)

2. White cement gets its color due to the absence of ______ and manganese.

(Answer: Iron oxide)

3. ______ cement is made by adding pigments to white cement.

(Answer: Colored Cement)

4. High Alumina Cement is made by fusing ______ and limestone.

(Answer: Bauxite)

FAQs on Types of Cement

Q1: Which cement is best for decorative finishes?

➡️ Colored or White Cement.

Q2: Why is PPC considered eco-friendly?

➡️ It uses industrial byproducts like fly ash.

Q3: What is the main use of Rapid Hardening Cement?

➡️ Road repairs and precast elements.

Q4: Which cement prevents cracks in dams?

➡️ Low Heat Cement.